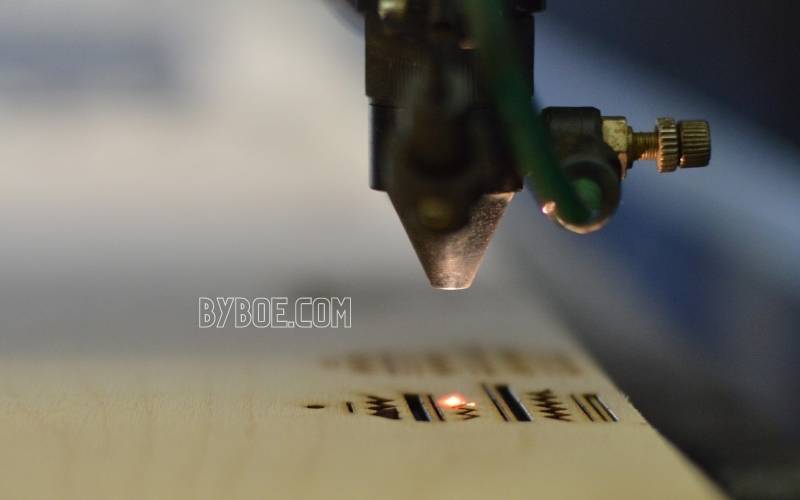

Laser engraving is a process that uses lasers to create text or designs on a variety of surfaces. The laser beam is focused onto the surface, which causes the material to heat up and produce a mark. If you want to know more about the process, keep reading this article, Byboe will show you How Does Laser Engraving Work? and things consider purchasing a Laser Engraver.

Table of Contents

- 1 What Is Laser Engraving?

- 2 How Does 3d Laser Engraving Work? How it Works

- 3 Benefits of Laser Engraving

- 4 What Are Lasers Used for?

- 5 Why Are Lasers Dangerous?

- 6 What Stops a Laser Beam?

- 7 What Is The Difference Between Laser Engraving, Laser Etching, and Laser Marking?

- 8 Factors to Consider When Buying a Laser Engraver

- 9 How Does a Laser Engraving Tool Work? FAQs

- 10 Conclusion

What Is Laser Engraving?

General engraving refers to carving or cutting a design into a material.

Laser engraving technology uses a laser beam to create the same effect.

A Brief History of Engraving

The laser engraving was the process used to begin the entire decorating process. One stone was used for laser marking another. The oldest known engraving quality in the world dates back to 500,000 years ago and is a doodle.

In 3000 BC, the Sumerian and Hittite elite started laser engraving intricate seals into precious gems and stones. Similar to today, engraving was used to decorate and design in ancient times.

Laser engraving was crucial for recreating documents and artwork in the 1400s. Wooden pieces were carved, and then the inked portions were covered in paint or ink.

The Printing Press consisted of many tiny laser engraving arranged in sentences and then pressed onto pages. Gutenberg!

Add in some significant technological advances, and laser engraving is back in the realm of decoration after its prominent stint as a source of printing.

How Does 3d Laser Engraving Work? How it Works

Laser engraving creates deep crevices by sublimating the surface of the material. The surface absorbs enough energy instantly to transform from solid to gas without ever becoming liquid.

Sublimation requires that the laser engraving system generate sufficient energy to enable the material’s surface to reach its vaporization temperature in milliseconds. Laser engravers are potent tools due to the extreme temperatures needed for sublimation.

When temperatures reach this point, materials are vaporized and converted into fumes. A fume extraction system and an air knife should be included in any laser system you purchase to protect your work environment.

Because they produce a wavelength that reacts well to metals, fiber lasers are ideal for laser engraving.

Benefits of Laser Engraving

Contactless Application

Laser engraving has the advantage of requiring no contact. Laser engraving uses heat instead of physical contact.

Laser engraving is more efficient than traditional engraving techniques because it does not cause any abrasion to the surface. Laser beams vaporize the area targeted and do not affect the surrounding areas.

Safety

Laser engraving is an alternative to traditional methods that rely on harmful chemicals. Laser safety eyewear protects your eyes against any potential dangers and harmful effects that fiber lasers may cause.

It is possible to use laser systems with computers. This means that they can be operated from a distance. Fiber laser engraving machines can be dangerous and require eye protection.

Versatility

Laser engravers can work on many materials. This versatility is a massive advantage for DIY enthusiasts and small businesses.

Different materials can be engraved, including plastic, metals, and ceramic. You can also change the speed of your laser systems to achieve different results.

Lower laser engraving speeds, for example, allow more prolonged laser beam exposure. This makes them more suitable for deeper engravings or cutting.

Precision and accuracy

You can create intricate patterns or personalized engravings with a laser-engraving machine. Laser beams work only on the target surface area to get 100% accuracy.

Used Across Multiple Industries

Laser engraving is very popular because of its precision and versatility. Hundreds of industries use laser engraving to make personalized gifts, corporate souvenirs, and customized jewelry.

Small businesses also use these laser engraving machines to create nameplates that label surgical instruments and automotive parts.

What Are Lasers Used for?

Laser light has many unique properties that allow it to perform diverse tasks. According to the FDA, lasers are used in a wide range of ways.

- Reading disks (Blu-Ray, DVDs, CDs)

- Speed and distance measurement

- Reading barcodes

- Scan documents with a printer

Your mom is yelling at you for shining it in your brother’s eyes (maybe not the FDA list).

Precious cutting gems can perform complex medical procedures.

It doesn’t matter what you do; someone is likely to use a laser system to accomplish it or find out how to do it.

Why Are Lasers Dangerous?

Laser light wavelengths can be focused on one point and can burn nearly any material without enough energy.

Protective glasses are a must for high-powered lasers because of the intensity of light.

Last, consider a laser beam’s sound when it hits an object. When powerful laser beams contact hard materials like chrome, they often emit high-pitched sounds. When using a laser, be sure to protect your ears.

What Stops a Laser Beam?

It is best to turn off the energy source as soon as possible.

For example, if a bad guy points a laser gun at you, grab the nearest mirror and deflect the light from your face. It is preferable to put the evil, mustachioed villain back on your face.

Another option is to block the laser by using another object. You will need a heavy, complex metal to stop the laser if it is high-powered.

What Is The Difference Between Laser Engraving, Laser Etching, and Laser Marking?

These terms are often used interchangeably. Laser etching, laser engraving, and laser marking all have their differences. Let’s see how they differ from one another.

Laser engraving: A laser beam that physically reduces a specific surface area. Laser engraving is best for materials like leather and wood. The best laser type for laser engraving these materials is the CO2 laser.

A laser beam interacts with a surface to modify its appearance or properties. A CO2 laser can mark organic materials such as wood, cardboard, and textiles. A fiber laser machine is best to keep metals and hard plastics.

Laser Etching is the laser engraving process by which a laser beam heats a material. This causes the material’s surface to melt. Laser etching is the best way to work on acrylic and glass objects. A CO2 laser will ensure excellent performance.

Each technique is unique and can be used for hobbyists, small businesses, or industrial projects. This makes it an all-purpose engraving machine that everyone can use.

Factors to Consider When Buying a Laser Engraver

Here are some things to consider when buying a laser engraver device to meet your engraving needs.

Material Size

Each laser-engraving machine is limited in the size of the designs or patterns engraved on a surface. Make sure to review the specifications of your engraver, including laser wattage, laser engraving area, maximum cutting thicknesses, and worked size. For engraving, large materials, some larger laser engraving machines have pass-through doors.

Features

To make engraving easier, ensure you look at the following essential features when buying a laser engraver of high quality. These are some helpful features to look for:

Air Assist

Some laser engraving machines have an in-built air aid, which improves efficiency and increases safety when applied.

Control Panels

Search for digital displays with intuitive buttons and push-button controls.

Pass-Thru Doors

Users can work with bulky or longer materials with the pass-through doors.

Connectivity

While most laser engraving machines have USB connectivity, some devices can also be connected via Bluetooth or a wireless interface at 2.4 GHz.

Safety certifications

Protective eyewear is essential to protect you from potential harm, but it’s also crucial that you buy a safe laser engraver. Check for safety certifications like FDA, CE, UL, IEC, etc.

Warranty

The machine that you purchase must have a minimum of a one-year warranty. So that you can have reliable after-sales support, it is essential to select products that offer a good warranty.

Trusted Source

The internet makes it easier than ever to buy a laser engraving machine. However, many online retailers sell counterfeit or low-quality products.

You don’t want your hard-earned cash to be wasted on a low-quality laser engraving machine. Instead, it would help if you always shopped at a trusted online store.

Through social media, such as Facebook or online forums, you can find out more about other users’ trusted brands and products.

How Does a Laser Engraving Tool Work? FAQs

What Kinds of Things Can Be Engraved?

You can engrave almost anything.

- Metal

- Wood

- Glass

- Plastic

- Leather

- Fiber

It can be engraved as long as the surface is hard.

The power of the light (PPI) and the number of pulses per inch (PLI) will change between different materials.

Clear laser marking is easier for soft materials such as wood and plastic. They require less power and less PPI. Too much emphasis can cause damage to the item you are trying to modify. Too little or too much PPI can also result in a nasty burn.

You will need more power and PPI for steel and other rigid materials to make a mark.

You want to strike a balance between power, PPI, and the material. This will ensure that the laser engraving is clean and doesn’t compromise the object’s integrity.

However, there is a lot of flexibility for laser engraver power settings so that you can fine-tune the laser engraving to your liking.

How Does Custom Engraving Work?

Now you are familiar with the steps involved in laser engraving. Let’s now talk about customization, which is the fun part. ).

Laser engravers can be very expensive, so many companies have them and do custom work for you. Two types of businesses specializing in engraving sell specific products that can be laser engraved, and the other focuses solely on engraving.

Conclusion

There are many ways to engrave an object, but laser engraving is one of the most popular. This process uses a laser to carve an image or text into an object. We hope our demonstration was helpful.