The Glowforge Basic is a 3D laser printer designed for home users. It is small and easy to use, and it can print a wide variety of materials. The Basic has a few limitations compared to the Pro, but it is still a powerful and versatile printer. In this Glowforge Basic Review, Byboe will show you all specs and features of this device. Let’s see whether it is for you.

Table of Contents

Glowforge Basic Reviews

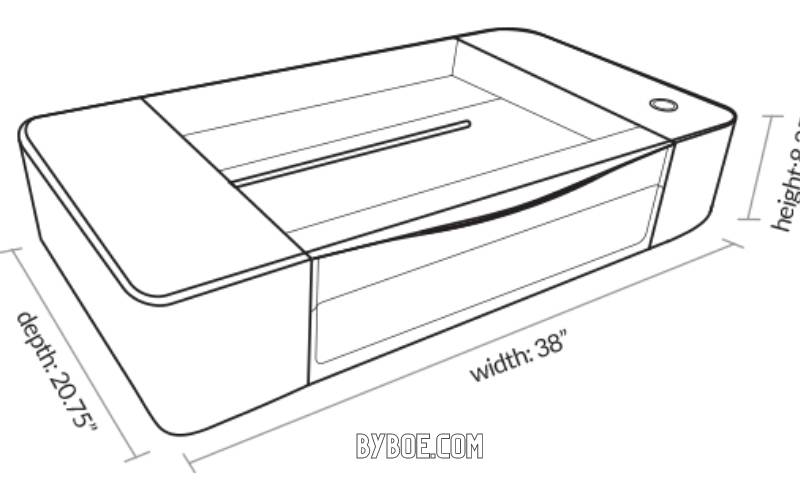

- External Dimensions: 965 x 527 x 210mm

- Dimensions of the Air filter: 965mm by 527mm and 178mm

- Maximum Depth of Material: 455 mm

- Full Material Width – 515 mm

- Cut Area: 495 mm wide, 279 mm deep

- Maximum Material Height – 50mm

- Height plus Tray – Maximum: 13mm

- Material Types: Fabric, Leather and Wood, Paper, Plexiglass. Cardboard, Delrin.

- Cutting and engraving rubber, mylar, sandpaper, cork, food, etc.

- Laser Engraving only: Marble, glass, stone, rubber stamps, ceramic tile, titanium, anodized aluminum, and others

- Connections: Windows, Mac, Linux, Mobile devices

- File Types: PNG and JPG. PDF and SVG.

- Wide Angle Camera: Lid Mounted. Complete Print Area View. 0.25” (6mm). Accuracy

- Larger Camera: Head Mounted, Close-up View with AutoFocus, 0.04” Accuracy

- Type of Laser: CO2 Laser-Proprietary CO2 Laser Tube Of Glass with non-stop operation at 10,600 nm and 40 watts.

- Alignment – Optical system factory set

- Sealed Lens (Optics: Protective encapsulated optical path that can be cleaned or replaced with Windows.

- Casing: High modulus injection of molded plastic

- Lateral System: Proprietary Extruded Aluminium rails aligned linearly with a v wheel carrier with belts.

- For Motion: Twin hybrid stepper for Y-axis; One hybrid stepper for X-axis

- For cooling: Internal cooling with circular enclosures

- Assist for air: Internal without the need to hookup an external compressor

- Ideal Temperature for Operation: 16-24

Pros and Cons

Pros:

- Affordable.

- Large print area

- Reasonably fast, powerful

- Uses a variety of proofgrade materials for laser cutting and etching.

Cons:

- Good ventilation is required, or a $1,000 Compact filter.

- Unboxing the Glowforge

What’s in The Box?

The Glowforge is contained in box 1. This item is heavy enough to require assistance. It was left on its side by UPS; the driver pressed my doorbell and then dashed. She is a strong woman, and I am grateful for her kindness.

The crumb tray, hose, and proof material selection are all contained in the second smaller box. The low price of Glowforge itself suggests that proof-grade materials are part of their business model and not just a way to sell machines. In a “give away the handle and sell the blades” kind of way, recurring revenue.

My box contained a good variety of items but nothing outlandish or unusual (veneer and Acrylic, draft board). I also got some leather pieces, which I will try as I planned to engrave my leather phone case.

Design

Glowforge Basic has the same size and shape as the Glowforge Pro. Glowforge Pro is a large-format printer that measures 8.3×38.0x21.0 inches (HWD). The large glass door folds up on the top panel and looks similar to a large-format printer.

The second metal door is located at the front of the laser. Open both doors to access the interior cavity and the 11.0-by-19.5 inch laser cutting area.

The cavity houses the laser head. It is attached to a coated metal arm. Thanks to tracks on its sides, it can freely move in all directions.

The cavity’s back is where the liquid-cooled laser tube is fixed. The bottom has a removable, black crumb tray that can be removed. This provides a place to store your work materials and allows for dust to settle.

Glowforge Basic laser cutter has a feeder slot, while the Glowforge Pro lacks it. Glowforge Pro can accept materials of unlimited length, provided you have enough space behind and in front of the laser to feed them.

Glowforge Basic laser cutter can only take pieces up to 18 in. Both lasers have cutting areas of 11.0 x 19.5 inches. This space is sufficient for many projects and much more than the Flux Labs Beamo’s 8×10-inch workspace (though it can fit on a desk with no problem). Even Epilog lasers have the exact space requirements as the Glowforge Basis laser cutter, with a 16×12-inch cutting area.

One of the few controls and status indicators on the Glowforge’s top is a large circular button in the lower-left corner. When it’s ready for setup, the button turns teal and then turns white. When it turns white, press the button to start a burn. Holding it down will force the laser into setup mode.

The only other indicator of the laser’s state is the button. The power switch is located in the lower-left corner, just next to the power connector. The Glowforge website is responsible for everything from turning on the Glowforge to starting a burn.

An exhaust vent is located on the back of the Glowforge. This connects to the flexible duct tube. Because of the dust and fumes they emit, burning lasers require ventilation.

You can run the duct through a window or purchase the optional $995 Compact filter. This box has an intake fan and large filter cartridge, which safely collects the exhaust from your Glowforge without any external outtake.

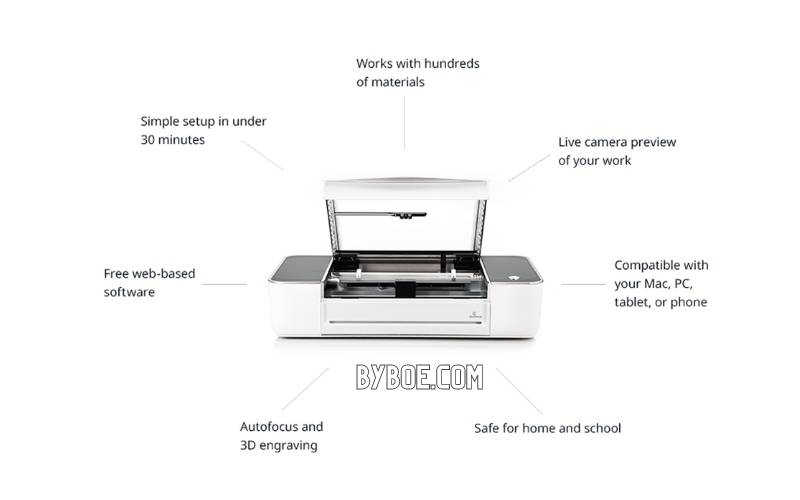

Setup and Software

You will first need to unpack the laser. Next, take out all the tape and brackets used to ship the parts. Then, connect the moving arm to the laser head by putting it on a magnetic mount and connecting a rhythm cable.

Please turn on the power switch, plug the laser in, wait for it to glow teal, then turn the power switch off. Glowforge’s web app will guide you through connecting to your laser’s wifi network and joining it. After that, you can begin burning.

Glowforge’s web app is easy to use. It accepts bitmaps for cutting and vector graphics for etching. The layer system allows you to arrange multiple cuts at once.

Drag and drop is all it takes to size your designs. A camera underneath the lid allows you to see most of the workspace.

Like every other laser, the Glowforge Basic laser cutter is very loud. Although the laser is quiet, it requires powerful fans to remove any dust or fumes that it produces.

These fans can be noisy, whether they are used with the compact filter’s intake fan or the laser’s exhaust with a duct that leads to the outside.

Material Cutting and Speed

Glowforge Basic can easily etch and cut multiple materials, such as Acrylic, leather, paper and rubber. You can also engrave any of these proofgrade materials, as well as anodized metals, ceramics, glass, or stone.

Glowforge sells its cutting material, such as Acrylic and wood, under Proofgrade. The protective film you use with Proofgrade materials will contain a QR code.

This will allow the powerful laser to identify the proofgrade material and set the correct laser settings. You don’t have to do this. Instead, you can choose from dozens of laser presets based on your proofgrade material or make your own.

Glowforge claims that the Basic burns at a third of the Pro’s speed but a 40-watt, less powerful laser. Despite this, the Glowforge Basic was fast enough to do test cuts and engravings.

The Basic cut the components of a box, a set of calipers and three plates of simple images from Glowforge’s sample projects on a draft board in less than 25 minutes. You can expect to burn longer for more extensive and detailed engravings, mainly if the HD Graphic option is used for better clarity.

Performance

Multiple test burns were performed with the Glowforge Base, cutting and engraving different wood and acrylic shapes. I accurately cut the other pieces of the draft board box and calipers, and they came out with clean edges.

The calipers’ measurement marks match the markings on a small commercial tape measure: millimeters, centimeters, and inches.

Although the markings on the more minor scales became a little smudged from removing the protective film before burning, the cuts and markings remained precise. The results would have been cleaner if I had kept the protective film on or used plywood instead.

The laser-etched the logo onto an acrylic plate, and the laser made the engraving visible. The laser created the symbol from a larger scale, producing even smoother edges.

Simple graphics and logos are simple, but photos can be difficult to burn. The Glowforge PRO, the Glowforge Basic, has Draft, SD and HD options for graphics and images.

However, complex photos may not be well served by these options because they dither laser pulses that create shading. The 3D Photo option handles shading differently by burning more plunging into the material to show the darker areas of the image.

This method produces better results if you prepare your photo correctly. It is a very technical editing process that involves turning any color photo from black and white to black and then sharpening it slightly more than usual.

After creating a photo of a friend with Paint.net, I did a test burn in clear Acrylic. The test burn turned out very well, with details such as the bus markings and the camera markings coming through clearly.

The beautiful details around the camera lens, such as the more minor markings, were a little challenging to see. However, the overall result is still excellent considering the size of the design (seven by five inches).

The walnut plywood was used to make the book-shaped box. The sides of the box are interference-fitted, and the spine is curved with parallel cuts that give the material enough flexibility to bend.

A sliding latch system is available that consists of three wooden plates and four teeth. This box is functional and technically impressive, especially for a quick 15-minute job. This box shows how creative you can be when using a laser cutter with various proofgrade materials.

What I Think Could Be Improved on the Glowforge

Perhaps it was just me, but I found that the instructions for setting up the wifi were more focused on the first steps and unboxing than the actual setup.

The problem is that the warranty folks ask you to keep all of your packagings in case it needs to be returned – I worry people might start to tear away or lose/damage packaging bits.

It’s not a huge deal, but it is aimed at people who have never used such a machine before. To make it more attractive to newbies, they call it a Laser Printer rather than a Laser Engraver. This is something that frustrates nerds.

The exhaust hose is short and fragile. We initially worked in the garage, so we needed a long hose to connect the Glowforge with the garage door.

Amazon sent me an inline fan as well as a more robust hose. But it is something I recommend if you are looking to get your machine up and running in no time.

Although you can buy a filter unit, it is not a long-term solution for those skilled in cutting clean proofgrade materials.

See my complete review of the Glowforge Compact Filter.

Although the webcam is fantastic, it is not always accurate due to its fisheye lens. It is still very cool to be in a position to see where your artwork drops on the screen.

Autofocus makes a huge difference. In May 2019, a calibration tool was introduced, allowing offsets to be eliminated. Although this covers 98% of the use cases, traditionalists like me still want a red dot or perimeter trace option to dial in multiple steps.

I initially suggested adding creative tools to the design software (e.g., crop, rotate and mirror), but the premium had the most excellent stuff.

We did purchase premium, and it has been beneficial. However, most people prepare all their work in their design packages. It would be even better to use LightBurn or other external software, but that is unlikely unless the company goes bankrupt.

Although a Pro model has pass-through, the basic model does have a front flap. It would be great to have “disable safety features” built in. See my tutorial on Glowforge Basic pass-through Hack. It involves magnets

We are also pretty screwed up by the shipping costs of Proof Grade materials in Canada until they reach a local distributor.

This is a pain because Glowforge’s end-to-end process is one of its greatest delights. We can also use proofgrade materials from local sources. We used to have a Montana mailbox that would reship my mail to Calgary for a fee, but they were unreliable due to the pandemic.

Glowforge Basic Laser Cutter Review: Conclusion

The Glowforge Basic is an excellent laser printer for those looking for an affordable option that still offers good quality prints. The device is easy to use and has a wide range of compatible materials, making it a versatile tool for various projects. While it may not be the best option for those looking for a high-end laser printer, the Glowforge Basic is an excellent choice for those just starting or who are on a budget.

ˈlāzər

ˈlāzər

tia laze