Glowforge Pro is a 3D laser printer that can print in various materials, including wood, leather, and acrylic. It has a built-in camera that allows you to view your print in progress and make adjustments. The Glowforge Pro is a high-quality printer that is perfect for professionals. If you consider investing in this device, keep reading the Glowforge pro review to know if it is worth buying.

Table of Contents

Glowforge Pro Laser Cutter Review

- External Dimensions: 965mmx527mmx210mm

- Dimensions of the Air filter: 965mm by 527mm and 178mm

- Maximum Material Depth – No Limit

- Maximum Material Width – 515 mm

- Cut Area: 495 mm wide, 279 mm deep

- Maximum Material Height – 50mm

- Height plus Tray – Maximum: 13mm

- Material Types: Fabric, Leather and Wood, Paper, Plexiglass. Cardboard, Delrin.

- Cutting and laser engraving rubber, mylar, sandpaper, cork, food, etc.

- Only for engraving: Marble, glass, stone, rubber stamps, ceramic tile, titanium, anodized aluminum, etc.

- Connections: Windows, Mac, Linux, Mobile devices

- File Types: PNG and JPG. PDF and SVG.

- Wide Angle Camera: Lid Mounted. Complete Print Area View. 0.25” (6mm). Accuracy

- Larger Camera: Head Mounted, Close-up View with AutoFocus, 0.04” Accuracy

- Type of Laser: CO2 Laser-Proprietary CO2 Laser Tube Of Glass with non-stop operation at 10,600 nm and 45 watts.

- Alignment – Optical system factory set

- Sealed Lens (Optics: Protective encapsulated optical path that can be cleaned or replaced with Windows.

- Casing: High modulus injection of molded plastic

- Lateral System: Proprietary Extruded Aluminium rails that are aligned in a linear fashion with a v wheel carrier with belts.

- For Motion: Twin hybrid stepper for Y-axis; One hybrid stepper for X-axis

- Cooling: Internal cooling with circular enclosures

- Assist for air: Internal without the need to hook up an external compressor

- Ideal Temperature for Operation: 16-27

Pros and Cons

Pros:

- It is easy to set up and use

- Simple web-based software

- A wide variety of proofgrade materials can be handled.

- Forums for active and valuable community involvement

Cons:

- Noise, odor

- Pro models are expensive.

- You can’t engrave material more significant than 5cm (2in.). Thick

- Materials that are proof grade are more expensive.

The Packed Box

- Below are some samples of subtitles

- These items are included in the Glowforge Pro packaging list:

- The Glowforge Pro 3D laser printer

- Laser Head by Glowforge laser engraver with a macro camera to autofocus

- A power cable

- Magnetic Lens Replacement Tool

- Crumb Tray made from steel.

- The Exhaust Hose

- Clamps for Hose Connection Rings

- Pro Shields

Design

Glowforge Pro comes in a large and well-protected box that measures 116.8cm x 71.1cm x 35.5cm (46in. x 28in. x 28in. It weighs 32kg (70lbs). The inside device measures 96.5cm in width, 52.7cm in-depth, and 21cm high (38in).

Dimensions: 20.75in. x 8.25in. It weighs 25kg (55lbs) and is a two-person lift. A sturdy table or desk with a minimum height of 2.5 cm (1in.) is required.

You will need at least 2.5cm (1in) clearance on all sides. If you plan to use the Pro’s passthrough slot to hold more oversized items, be sure to leave more space to the front and back.

The three models can print materials up to 20.4 in wide, 18 inches deep, and 2 inches thick. By 19.5in. Using the Pro’s pass-through slot, you can publish materials up to 20 inches in width and a quarter-inch thick. The material can be printed 10 inches at once; then, the slot will slide the fabric through to process the next section.

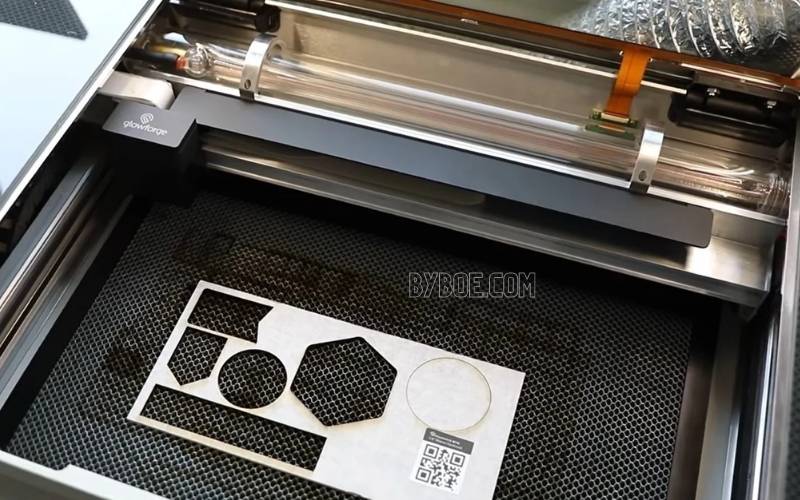

The Glowforge laser engraver includes an accessory pack. It consists of the black metal crumb plate, an exhaust tube that clamps to the back of the device, and a starter pack with Proofgrade materials.

A selection of woods, MDF, acrylic, and leather, were available. The official Proofgrade materials have a peel-off protective coating on each side and a QR code that Glowforge’s camera can read to determine the correct settings.

You will need to verify the CO2 laser compatibility of any third-party materials and select the correct settings. The Glowforge laser engraver community can address this issue, which is also helpful in many other ways.

You have two options to dispose of the exhaust hose’s odor and dust. Either you can direct the hose outside via a window or vent or attach it to an optional air filter unit.

This unit is heavy in both weight (22kg/48lbs) and cost ($995/PS901.62) and comes with replacement cartridges that cost $250 or PS187.96. The expected cartridge lifespan depends on the type of paper you use and how long.

Glowforge Pro looks big. It has a white plastic case with a lid and top and a camera underside. The cover reveals the rail-mounted laser tube/arm/printer head mechanism and the crumb tray.

The front door opens to reveal the insides. There are passthrough slots in the back and front for oversized materials. This is only available on the Pro model.

The power input, on/off switch, and exhaust connections are located at the back. On the right-hand side of the front is a large circular button that flashes white. This indicates that the Glowforge laser engraver has been printed and is ready for you to press.

Features

Glowforge’s three models, Pro and Glowforge Basic are very similar. It is only the logo on each lid that distinguishes them. Although the technology inside is very similar, it differs with each model. The Glowforge Basic and Pro models have a 40W laser, while the Pro has a 45W laser.

The Pro model’s custom CO2 laser tube works at 10600 nm 45W. Because of this, it requires some additional training and safety precautions. The Pro model has 120% more power than other Glowforge models.

The Pro model also has enhanced cooling, which is a must-have for anyone who uses the laser cutter professionally. The Glowforge Pro can therefore be used all day happily without excessive heat.

You can choose from various materials, including plastics, wood, and leather. Glowforge laser engraver makes its products, which are both high-quality and expensive.

Materials can be purchased from other sources, but they must be laser-ready. For example, non-laser ply uses laminate glue, making it difficult to cut in this way.

There are many options available. You will need to cut the material to fit your needs as these materials may not be standard.

Glowforge’s materials make maximum use of the bed. They measure 30.4 cm by 51.8 cm and have a printable size of 27.9 cm by 49.5 cm. With the tray removed, the laser can also cut materials up to 1.2cm or 2cm.

Glowforge laser engraver can read JPG, PNG, and SVG files. If you subscribe to Glowforge Premium, you will also receive support DXF files.

The Glowforge PRO’s main feature is its pass-through slot and the upgraded components. This simple slot allows more extensive materials to be fed through the printer’s front and back.

The material’s width is restricted to 51.8cm. However, the depth of the materials can be as high as 0.9cm.

Installation

Unpacking the Glowforge laser engraver will reveal a large label at the top. This prompts you to log in to the Glowforge setup site and follow the instructions to get started.

These instructions are simple. It takes only a few minutes to get connected and start. Although the laser printer was recognized, I found that Wi-Fi connections to the Mac Pro (late 2013) did not work. The link went smoothly after connecting to the newer commercial laser cutters, and Glowforge Premium’s trial period appeared.

Once you have completed the initial setup, the print dashboard can be accessed by signing in to the Glowforge website. Click create to access it.

Glowforge Laser engraver hosts laser cutting software, unlike other options. You can create and design your creations using almost any design software, but you will need their software to print.

You get a free trial of Premium when you purchase your first Glowforge laser engraver. This gives you access to many templates you can download and print. It also supports DXF files.

Faster printing is possible because powerful servers process the prints. There are household logins and other features that allow you to create and share ideas with others.

If you use Glowforge professionally, the Premium subscription will give you access to many community features. The free designs and faster printing speed are well worth the premium subscription. Glowforge offers an 18-month subscription for hobbyists. This brings down the cost.

Once everything is set up with the web interface and the laser cutter has been turned on, the camera mounted on the lid shows you a preview of the material cutting bed. The web interface allows you to import your design and place it on the material in your preferred position.

Glowforge materials have a QR code that allows the laser cutter to automatically recognize the material and adjust settings. You can choose from various options to find the correct settings using third-party materials. A Glowforge product is often selected, and the grounds are adjusted to achieve a great result.

You have the option to choose to Engrave or Cut, Score, Ignore, and then click to assign. Each setting allows you to select the outline of the path(s) from the file that you have imported and then click on the button to assign. It’s easy even for non-tech-savvy users.

You have three options when it comes to importing a pre-designed file. Click the Create button to begin the process.

You will need to subscribe to the Premium subscription to access the New Blank design. This allows you to use many tools to create shapes and designs. It also gives you access to a vast selection of pre-designed-designed templates that you can use and customize.

Upload files allow you to import many different files. Different file types allow for varying adjustment, laser cutting, and engraving options.

You can load a JPG and use the bitmap options to adjust speed and power. You can engrave your design on the material. You have complete control over how Glowforge laser engraver handles the file using an SVG or DXF. You can export a basic structure from adobe illustrator to an SVG file imported into Glowforge software.

Initially, the path or paths in the file will be grouped as one object. You can then apply laser settings to that group.

If the file has more than one path, you can separate it into several steps. Each step can have different settings.

You can choose to ungroup by right-clicking and then cut and paste a path as a new step. Each Path can then be handled separately as Cut, Score, or Engrave. After the laser turns on, it recognizes each path’s power and speed differences.

The Trace feature is the last option. This is the most potent option and allows non-tech-savvy users to access advanced creative technology.

All you have to do now is draw the design on paper and then put it in the Glowforge laser engraver. After scanning the path, the software will assign the laser cutting paths.

It can take some time to navigate the settings and options in the Glowforge interface. This requires a strong network connection. Two types of wireless connections are needed.

This allows the computer to communicate with Glowforge team, and the second is to enable browser-based software access to Glowforge to process the file.

Performance

Glowforge Pro is a simple and elegant solution that you will discover as you use it. The web interface allows for fast file processing and gives you flexibility when engraving, scoring, or cutting, depending on what files you import.

The camera will show you the material overlayed with the design by loading in one pre-designed file. Click and drag the structure to its desired position.

This is simple enough with the provided proof-grade materials. Despite this, printing on almost any material is easy and quick, thanks to the ability to drag your design to the precise point.

Printing with Glowforge files yields a great result. Also, a quick review of the Glowforge startup tasks will help you understand what you can do with your laser cutter.

These are significant starting tasks that show you how to personalize the designs. But it is only when you begin to experiment with your content that the laser cutter comes to life.

After loading in an Illustrator design and exporting it in SVG format, I can split each design path into a new step by ungrouping them. After this is complete, I can assign Cut Score or Engrave each course.

If you use Proof Grade materials, the material and laser power settings will be automatically sorted. These materials have a QR code that the laser cutter recognizes and automatically applies the right settings.

These materials are more expensive than generic laser-ready materials. However, it is possible to choose the type of material and the thickness manually if you opt for the cheaper route.

Regardless of what you do, once your laser settings have been set correctly, you can click print from the browser interface. At that point, the large button lights up on the machine. One push of the button will start the printing process. The laser fires up, and the printing begins.

The process of converting your design from a laser engraver software program to materials is much easier than with other laser cutters. The design preview and camera material remove all guesswork. It is the most precise and easy-to-use printer I have ever used.

It is also highly reliable. There are no errors, no messing with laser heights, focusing, or guesswork.

You can use a RAW file you’ve created to show the machine’s full potential. This is fine for those familiar with Illustrator or other packages that can export files in required formats.

The Trace feature is a much more impressive option. This allows you to place a drawing directly under the camera. It’s then scanned, traced, and printed.

You can click on each traced path and assign Cut, Score or Engrave to your premium subscription. It’s sometimes more challenging to discern the directions if you don’t have a subscription. However, there are ways around it.

You can also click to ungroup and split the paths by clicking on the line drawing you created in Illustrator. This can take some time, depending on how complex the project is. It allows you to achieve stunning results and great flexibility.

Note on Materials

I used the Glowforge pro of grade materials for the test. These materials are highly accurate in thickness and quality. After a surprisingly short time, I had used up all of the Proofgrade stock and was forced to purchase other laser-proof materials.

These don’t come with the QR code for quick recognition. You will need to choose the thickness and material type; then, you’ll have to experiment with the power settings. Once you have mastered the material, it is time to run some tests and then write down the settings.

Other manufacturer materials produce results that are as good as the proof grade. However, there are a few additional steps. Although some materials may need to be cut, the results are generally excellent.

The Glowforge Pro version of this machine also allowed me to access the pass-through slot. The device can now be used for more extended materials, which is great because it easily fits through the space.

It is easy to use the pass-through slots. Remove the plates and select the pass-through slot setting from the software. Once each file is cut, push the material to the following location, align the design, and print the next section. It’s easy but very effective.

Use the Glowforge

After creating an account and connecting your laser to the network, you can access the Glowforge web app to use the device. You can then view your Glowforge’s bed through the preview camera, upload images (most formats supported for engraving, but vector art files such as.

SVG is required for cutting, aligning, and scaling your designs, and set the type and amount of material to burn; and finally, starting your project.

This intuitive, straightforward system lets you put multiple image files for a single burn and place each component individually before starting the project.

You must ensure that the image is appropriately set up for engraving. This is not a problem with simple symbols and logos. However, etchings made from photos will require some image editing using an app like GIMP, Paint.net, or Adobe Photoshop.

Glowforge offers some guidelines on how to prepare pictures. You will need to convert your image into black and white, sharpen it and adjust the levels to get the histogram towards the middle.

Glowforge’s web app has dozens of material presets. It can scan QR codes on fabrics purchased from the company or include them in sample project kits that came with the laser cutter to set the laser correctly.

You can also manually set up burns using various settings such as intensity and laser speed. The material presets worked well for me.

I was able to get the desired results with the medium setting of Glowforge’s acrylic and other acrylic panels that I purchased from Canal Street Plastics in Chinatown. These materials also worked well with the draft board, and plywood presets.

It can be time-consuming to engrave items, especially if they are very detailed. Glowforge has many settings for drawing and photos. These include Draft, SD, HD graphics, and 3D Graphics. The majority of graphic and photo settings use dithering for different light levels or darkening on engravings. However, the 3D settings adjust the laser intensity to create darker areas of an image.

The size and detail of each burn will affect the time taken. An hour and a quarter for a Draft Graphic burn on an 8-by-12 inch piece of acrylic, while three hours might be required for a 3D Photo (a 3D photo with depths that vary based on the darkening of the image) burn. An HD Photo burn can take six hours. It takes only a few moments to cut flat acrylic and wood pieces.

As I have already stated, you must be aware of potentially hazardous fumes from the Glowforge. You don’t want vaporized wood and other substances in your lungs if you don’t run your exhaust hose through a window or into an optional compact filter.

Although lasers are almost silent, your burns can still be very loud. The built-in fan of the laser’s duct hose will spin quite loudly when it is running out of a windowsill.

The filter’s noisy intake fan will turn most of the time when the hose is connected to the compact filter. The Glowforge is not quiet, no matter how you set it up.

Glowforge Pro Reviews: Conclusion

We tested the top-end Glowforge Pro set up with the air filter unit. It costs $6,990 or PS6,897 ($/PS5,995 + 995 or PS902). The official Proofgrade materials are also expensive and in limited supply in the UK.

Glowforge has seen a higher demand for Proofgrade materials than we expected since launching in the UK. Glowforge stated that they are doing their best to satisfy this demand and ensure that every UK customer receives Proofgrade materials.

You can find more affordable third-party materials online and at retail stores. However, it is up to you to determine their laser compatibility and apply the appropriate settings in the web application. Glowforge Premium subscriptions are also available at a discounted price of PS19.39 per month.

If you are willing to let the exhaust go out of a window, the cost of the Plus model can be reduced to $/PS3,995 with slower engraving speeds and cutting speeds.

This is a significant savings of approximately $2,995 and PS2,902 over Pro+air filters. The Glowforge Basic model is $/PS2,995 if you are willing to accept a slower engraving speed and half the warranty.

The Glowforge Pro is a 3D laser printer designed for the home user. It is easy to use and has a small footprint, perfect for the home office or workshop.

The Glowforge Pro can print in proofgrade materials, including wood, leather, and plastic. Byboe hopes that our Glowforge Pro 3D Laser Printer Review can help you know if it is suitable for you.