Fiber lasers are a type of laser used in many different applications such as engraving, cutting, heating, and other forms of construction and manufacturing. The fiber they use is very narrow in diameter, making it easy to direct the laser from the outside of the thread to the inside of the fiber.

So, How Does a Fiber Laser Work? Keep reading our article; Byboe will show you all you need to know about this laser.

Table of Contents

- 1 When Was the Fiber Laser Invented?

- 2 What Are the Types of Fiber Lasers?

- 3 How Does a Fiber Laser Work?

- 4 How Long Does a Fiber Laser Last?

- 5 Which Materials Can Be Processed Through Fiber Lasers?

- 6 Why are Fibre Lasers useful?

- 7 What Are the Laser Parameters?

- 8 What is a Fiber Laser Machine?

- 9 What’s the Difference Between Fiber Lasers and CO2 Lasers?

- 10 How Does a Fiber Optic Laser Work? Conclusion

When Was the Fiber Laser Invented?

Elias Snitzer invented the fiber laser in 1961. He demonstrated its use in 1963. However, severe commercial applications of the fiber laser were only discovered in the 1990s.

It took so long because of this. Fiber laser technology was still very young. This is the main reason.

Fiber lasers could only produce a few tens or even dozens of milliwatts, whereas most applications require a minimum of 20 watts.

As pump laser diodes were not as efficient today, there was no way to generate high-quality pump lights.

These are the most critical moments in the history of fiber laser technology’s foundations, which date back to 1917.

1917 – The discovery of stimulated emissions (Albert Einstein).

1957 – The theoretical framework of the laser is created (Gordon Gould).

1960 – (Ted Maiman) The first laser, a ruby laser, is constructed.

1960 – The first continuous-wave fiber laser (CW fiber laser

) is created as well as for ultrashort pulse laser.

1960 – Fiber optics is first used (Narinder Kapany).

1961 – The invention of optical modes in glass fibers (Elias Snitzer).

1962: Q switching, a method to generate pulsed laser beams, is demonstrated (Robert W. Hellwarth, R.J. McClung).

1963 – First fiber laser demonstration (Elias Snitzer).

1964 – The method of removing impurities from glass fibers and limiting light loss is discovered (Charles Kao, George Hockham).

1988 – Elias Snitzer shows the first double-clad fiber laser.

1990 – A 4W erbium-doped fiber laser breaks the watt barrier

2004 – The single-mode silica fiber laser was created, and David N. Payne invented an amplifier.

Fiber laser technology is still making significant advancements, making it more powerful, accessible, and efficient.

Laser cleaning and laser texturing are two of the most exciting applications. These technologies can replace polluting technologies and make the world cleaner.

What Are the Types of Fiber Lasers?

Fiber lasers can generally be classified using these criteria:

Laser source: The material mixed with which the laser source is made can affect the type of fiber laser.

Examples include erbium and thulium-doped lasers, erbium lasers, and ytterbium lasers. Because they emit different wavelengths, all these laser types can be used for other purposes.

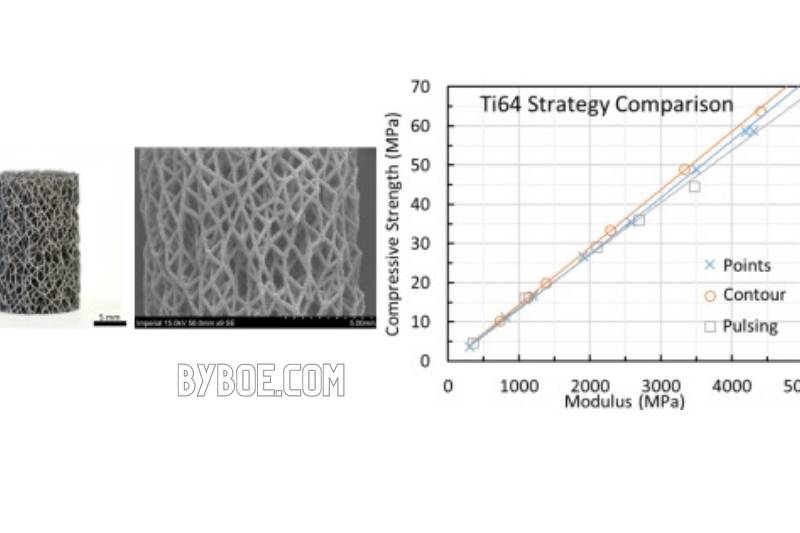

Mode of operation: Different laser types release different laser beams. Pulsed high-power fiber lasers can emit laser beams at high peak powers by pulsed at a fixed repetition rate (pulsed laser beams).

The pulsed fiber lasers are possible with “q-switched”, gain-switched, and “mode-locked”. They can also be continuous (continuous-wave fiber lasers), which means they continuously send the same amount of energy.

Laser power: The average power of a laser beam is expressed in watts. You can have a 20W fiber-laser, a 50W fiber-laser, etc. High-power lasers produce more energy than low-power ones.

Mode: Mode refers to how large the doped fiber core is (where pump light travels in an optical fiber). There are two types: single-mode and multi-mode fiber-lasers.

Single-mode lasers have a smaller doped fiber core diameter, usually between 8 and 9, while multi-mode lasers have a larger core diameter, usually between 50 and 100 millimeters. Single-mode lasers transmit laser light more efficiently and produce a higher laser quality.

How Does a Fiber Laser Work?

Laser stands for pump light Amplification through the Stimulated Emission of Radiation. This may not sound very interesting, so let’s try to explain it.

Light amplification refers to making more of the same pump light, just as an audio amplifier takes sound and makes it louder.

Scientists understand the meaning of stimulated emission in this context. It refers to the physical process that creates light. We need to understand a few facts about atoms to understand this.

You might be familiar that atoms are composed of electrons orbiting around a nucleus. These electrons are generally in a low orbit called the ground state.

They can be placed in a higher orbit if they receive more energy. This is called the exciting status.

They can only be placed in specific orbits around an atom for various reasons, including quantum mechanics.

These orbits are determined by the properties of the rare earth elements and cannot be altered. Gold, for example, has one set, oxygen and sodium have another. Each one is unique, so not all are suitable for our purposes.

An electron can return to its ground state when it is in a higher orbit (an excited state) or if it is in a higher orbit.

This process is called ‘decay. It must lose energy to do this. This is often done by emitting a photon, which is light.

The reverse process is used to get an electron to a higher state. To move an electron to a higher state, it absorbs a photon.

This happens because the photon’s energy must match the energy required to lift the electron into that orbit.

The photon that passes must have the correct amount of energy. The type of material is a significant determinant of the amount of energy required.

After an electron has reached a higher level, it will continue to exist there for some time before naturally returning to its ground state.

This is mere emission and not stimulated emissions. We don’t want that. A photon with the same frequency passes through, encouraging the electron to decay at that point. This is called stimulated emission.

The energy that a photon receives determines its frequency or color. If all photons have the same point, they will be the same color. This means that atoms emit light of the same color when encountering a specific material.

But electrons are excited to higher states, and drop-down gains don’t happen by default, or at least not often enough for us to notice. We need to make it happen.

Practical lasers work this way:

The first is to push electrons higher into a higher orbit. This is known as pumping. There are many ways to do this, but the most common is to bombard the atoms in light to increase their electrons.

The electron is usually unstable and will move quickly to a lower one. We need it in a metastable state for our purposes. The electron will stay around for a while before returning to its ground state.

A laser material must have a metastable state corresponding to a proper amount of energy. Laser material can quickly slide down to a lower meta-stable level after it has been pumped to a higher status.

We now have lots of electrons with the right amount of energy. They are waiting to be stimulated to give that energy up as a photon.

It takes just one electron to drop down and release a photon. This will trigger a cascade. The photon that passes through another electron in the metastable state will encourage it to drop down and release another photon.

We now have two photons. Each photon can enable two electrons to emit. This is called stimulated emitting’ because the photons stimulate the electrons to produce more photons.

The photons encourage one another to exist by being one color. They are all one color and all move in the same direction.

We now have an army made up of photons that march in unison, something you won’t see in nature.

It doesn’t work very well if all the photons leave the material at this point. To encourage more photons to emerge, we must keep ‘pumping’ electrons up to make them ready to emit them.

This is done by placing two mirrors at each end of the material (the ‘laser medium’). This active laser medium creates the laser cavity. Mirrors reflect light forwards and backward. On every roundtrip, more photons are created.

The laser cavity must be let out to make the newly created laser helpful light. One of the mirrors does not reflect all. It lets only a small percentage of the light through, which is our laser beam.

How Long Does a Fiber Laser Last?

Many online sources claim fiber lasers can last for 100,000 hours, while CO2 lasers only last 30,000 hours. However, this is not true.

These numbers are based on a value called mean-time between failures (MTBF). This value is not the same for all fiber lasers. You will see different numbers depending on the type of fiber laser.

The MTBF is a measure of the laser’s reliability. It indicates how long the laser can function before it fails.

This is done by testing multiple laser units and dividing total operational hours by complete failures.

This value doesn’t necessarily tell you how long a laser fiber can last, but it does give an idea of its reliability.

You won’t be able to determine the lifespan of a fiber laser if you try hard. Fiber lasers can fail at specific points during their life.

These are the things you should know if your laser has a failure.

Early life: Fiber lasers can fail early in their life. So that your laser can be repaired or replaced without any fees, it is essential to have a warranty on the purchase.

Everyday life: After you have passed the first crucial period in your early life, the MTBF value gives you an idea of the likelihood of your laser failing.

High MTBF does not guarantee that things will go well, but it is a good indicator. There are many ways to prepare for failures in your everyday life:

- Keep a spare laser on hand.

- Rent a laser while you repair it.

- Take out a long-term purchase guarantee.

End of life: Fiber lasers nearing their end-of-life are at greater risk of failure. A high-quality industrial laser can still operate well beyond its MTBF.

Which Materials Can Be Processed Through Fiber Lasers?

Fiber lasers can work with many materials and are reliable and experienced. Fiber lasers can work with many metals, including stainless steel, titanium, iron, and reflective metals like aluminum, brass, copper, and precious metals like silver and gold.

They are also compatible with materials that have anodized or painted surfaces. The processing of silicon, gemstones (including those made from diamonds), plastics and polymers, ceramics, composites, ceramics, ceramics, clays, composites and thin films, bricks, and concrete is possible with fiber lasers.

Why are Fibre Lasers useful?

A fiber laser’s first advantage is its stability. An optical fiber is required to move a laser beam safely. You can bounce it between mirrors, but they must be precisely aligned.

It is challenging to combine a laser beam with a fiber core. This also requires fine adjustment. Normal lasers are sensitive to being banged or knocked, so it is best to have an expert fix them.

On the other hand, the fiber laser generates the beam within the fiber. This means that the beam delivery doesn’t require sensitive or complicated optics. It is stable and straightforward to use.

A fiber laser’s second advantage is its beam quality. The fiber core is where the beam is created and kept contained.

This means that the shaft is straight and focused on a small dot. This is a requirement for many laser applications.

They can also be tuned to extremely high power. At around 1 Watt, lasers can cause severe skin damage.

Although this isn’t as powerful as a kettle or toaster, it can cause severe skin damage if concentrated on one point.

This is the difference between being warm by the sun and having it focus on you, creating powerful beams.

Fiber lasers keep getting more powerful and produce over 1,000 Watts (1kW) of power. This is enough power to slice through an inch of steel.

Fourth, they are highly efficient and easy to cool. While other lasers can only convert a fraction of the power they receive, a fiber laser can convert 70-80% of that power from the pump light source.

This is more efficient in terms of power consumption but also means that less heat is being generated.

Because the fibers are often quite long, the heat is evenly distributed across the length of the thread, which prevents it from becoming too hot and causing it to break.

The fiber laser system quality can be affected because almost all materials alter their optical properties when they heat up.

What Are the Laser Parameters?

Different lasers and applications have other parameters. Laser marking and laser cutting, for example, require additional parameters.

However, some parameters can be used for all types and models of fiber lasers. These are the most common.

A fiber optic cable produces wavelengths that correspond to the intensity of electromagnetic radiation. Optical fiber lasers typically have wavelengths between 780 and 2200 nanometers.

This wavelength is in the infrared spectrum and is not visible to the human eye. This infrared range is helpful for many materials processing applications because it reacts well with metals and rubber.

Some optical fiber lasers, such as green lasers, produce visible laser light that can react with soft materials like gold, copper, and silicone. Green fiber lasers can also be used for therapy, surgery, holography, and other purposes.

These lasers need additional components to produce visible laser light. John Wallace, Laser Focus World, explains how it works:

Mode of Operation

Mode of operation refers to how the laser beam can be released. Optical fiber lasers are typically operated in either the pulsed or continuous-wave modes.

The continuous-wave operation mode releases a continuous, uninterrupted beam of laser light. This is great for laser welding and laser cutting applications.

The pulsed mode uses short pulses at a fixed repetition rate. Pulsed laser beams have higher peak powers, making them ideal for laser engraving or cleaning. These parameters are part of this mode:

Pulse Energy: Pulse Energy is the number of millijoules in each pulse. Each pulse typically contains one mJ energy.

Pulse Duration: Pulse Duration is also called pulse length or pulse width. It refers to the time that each pulse lasts.

Pulses with shorter durations are more efficient at concentrating the same amount of energy over a shorter period, thus reaching higher peak powers.

You can express the pulse duration in microseconds (or nanoseconds) or picoseconds (or femtoseconds).

Pulse repetition rate: This is the number of pulses released each second. This is also called the pulse frequency and is expressed in kHz. 100 kHz equals 100,000 pulses per second.

Power

Laser power refers to the energy produced by the laser in one second. This is also called average power or output power.

Pulsed lasers, another parameter, can also indicate peak power. Peak power refers to the maximum energy achievable by one pulse.

A 100W pulsed fiber laser with 10,000W peak power can quickly achieve this. Pulsed lasers don’t distribute energy evenly over time, unlike continuous-wave lasers.

Beam Quality

The laser beam quality measures how close the beam is from what is known as a Gaussian beam. This is important in actual applications because it shows the laser beam’s focus.

Mathematically, M2=1 is the ideal laser beam quality. Well-focused laser beams concentrate more energy in a small area. High-quality laser beams will be required for applications such as laser engraving and cleaning.

However, lower laser beam qualities might be better suited for applications that do not require ablation, such as laser welding.

What is a Fiber Laser Machine?

A fiber laser machine is a system that has been engineered to produce a fiber laser solution that can be used immediately. The OEM laser system is what operates. However, the laser machine is where the tool is integrated.

Fiber Laser machines can ensure that:

- Laser safety and fume extraction ensure workers are 100% safe

- To automate or simplify the work of operators, mechanical components are used

- Laser processing is tuned to a particular operation

For example, the fiber laser machine is shown here, for example, includes a rotary desk, an indexer, a Class-1 safety enclosure, a fume extraction, and a vision camera.

What’s the Difference Between Fiber Lasers and CO2 Lasers?

The source from which the laser beam is created is most different between fiber lasers and CO2 lasers.

Fiber lasers use silica glass and a rare-earth element as the source. The laser source in CO2 lasers is a mixture of gas, including carbon dioxide.

Fiber lasers can be considered solid-state lasers due to their light source, while CO2 laser systems can be regarded as gas-state.

These laser sources can also produce different wavelengths. Fiber lasers have shorter wavelengths.

Some examples range between 780 nm to 2200 nm. However, CO2 laser systems produce longer wavelengths ranging from 9,600 nm to 10,600 nm.

Because of their different wavelengths, they can be used in other applications. 1064 nm fiber-lasers best serve metal processing uses.

Laser cutting is an exception. CO2 lasers are preferred for cutting metals. Organic materials also react well to CO2 lasers.

How Does a Fiber Optic Laser Work? Conclusion

A fiber laser is a laser in which the light is generated by the optical amplification of light in a fiber optic cable. This fiber optic cable is the principle behind the use of a fiber laser.

In most cases, the light produced by the laser does not penetrate more than one millimeter into the fiber optic cables. We hope that our guide can help you learn more about How Fibre Lasers Work