Uv resin vs epoxy is both types of resin, a substance used to manufacture products such as adhesives, coatings, and fiberglass. They differ in how they cure or harden. Uv resin cures when exposed to ultraviolet light, while the epoxy cures through a chemical reaction between the resin and hardener. Keep reading this article, Byboe will let you know What’s The Difference between them?

Table of Contents

What is UV Resin?

UV resin is one of the many synthetic resins that can be made industrially by polymerization. To cure, this resin needs energy radiation from UV light.

You can get ultraviolet light from a flashlight, lamp, or the sun. The UV resin will harden almost instantly when exposed to ultraviolet light. A photochemical process does this.

This is what makes UV resin so popular: the short time it takes to cure. It might even be called the resin for the impatient by other crafters.

UV resin can also be used as a one-part resin. It doesn’t require unique mixing or preparation and is cast straight out of the container.

It will not thicken until UV light is applied, so the time frame is flexible. The resin is watertight so that you can take your time in pouring and embedding.

It is easy to work with UV resin, but it isn’t always easy. There are still challenges to overcome. One example is the resin, not hardening after being exposed to UV light for a while.

This could be due to various factors, but insufficient light intensity is the most likely reason. To cure UV resin properly, it must be heated.

When choosing a UV device, make sure it emits long wavelengths. Long wavelengths penetrate deeper into resin than short wavelengths, which only heat it superficially.

Sometimes, non-curing is not related to the quality of the sunlight but rather blockages that prevent deep penetration. Opaque molds, excessive glitter, and pigments can block UV light.

You may have poured the UV resin too thick. UV resin should not be applied thicker than 3mm. 4mm if you push your luck.

Any more comprehensive than this will have problems curing. If you have to go large, make sure you do so in thin layers and allow ample curing time between each layer.

UV resin, once hardened, has a stunning pristine clarity, but it is not very long-lasting. High heat and scuffing can easily cause UV resin to become brittle. It has a 6-month shelf life. To avoid wastage, the resin is only sold in small quantities.

If you require large quantities of resin, buying small bottles can quickly become expensive. The UV light device is also costly because UV resin can be costly.

To see more information about UV resin, let’s check out our articles right now:

What is Epoxy?

A synthetic resin is an epoxy used for casting, UV, and polyurethane. It is manufactured using chemical polymers. Epoxy is a two-part resin. This means that epoxy must have a hardener for the curing process to occur.

This resin will be sold in two bottles. The epoxy is one part, while the hardener is the other. For the best resin-hardener reaction, measurement accuracy is crucial. The two components must be equal and thoroughly blended. Otherwise, the resin will not harden.

You will need to measure accurately and work quickly because this resin is not as flexible as UV resin. The mixture begins to thicken once the resin and hardener are added.

Bubbles are also formed by trapped air. To achieve a perfect appearance, these bubbles must be removed with heat.

Epoxy is more complex than UV resin and requires more skill to succeed. It would help if you were patient, as curing can take 2-4 days.

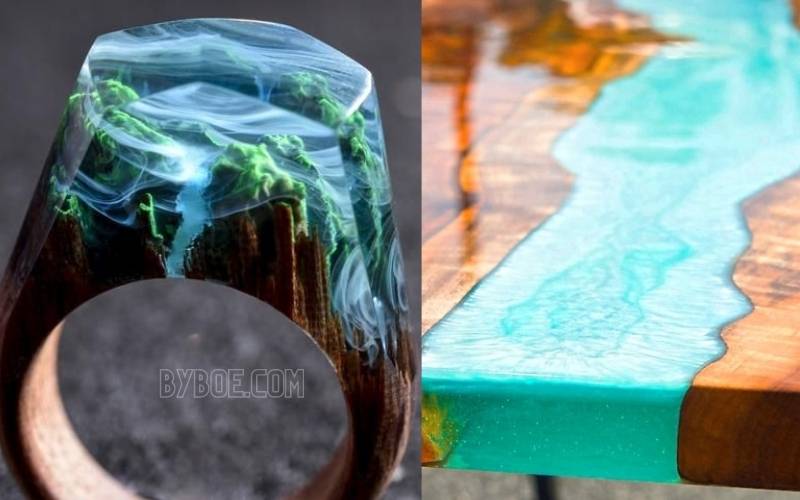

It’s a long process that takes time, but the result is worth it if the resin is cured correctly. The epoxy resin hardens to a rock-solid, high-gloss, transparent, crystal-clear mass. It is highly resistant to heat and scratches and very durable.

You can find epoxy resin in many quantities, from a few ounces to several gallons. Because epoxy resin has a longer shelf life (3 years), it is more affordable. Any leftovers can be used for 6 months after the seal has been broken.

It is also available in large quantities because epoxy can be cast thicker than UV resin. It is possible to pack more significant amounts of epoxy in a single layer up to 5cm.

Which is Better? Uv Resin Vs Epoxy

Before we get into the details about UV resin vs. epoxy resin, let’s first understand how these resins work. To harden UV resin, a UV torch or lamp is used. Epoxy resin is a mixture of resin and hardener. The epoxy resin is not mixed like the UV resin.

Both epoxy resin and UV resin have distinct features that make them better for specific situations. The main differences are mixing, cost, durability, curing and curing.

Both resins can be used for similar projects, but there are significant differences. Let’s have a closer look at what the differences are between the epoxy resin and UV resin.

Uv Resin and Epoxy: Mixing and Curing

The mixing and curing process makes epoxy resin different from UV resin. Epoxy resin is made up of two liquids, resin, and hardener.

Mixing these liquids causes a chemical reaction, which causes the mixture to harden. The resin forms a solid, transparent, glossy surface.

On the other hand, UV resin is a one-part resin that is ready for use immediately. There is no need to measure or mix when working with UV resin.

The resin must be exposed to UV lamps or a torch to harden. This type of application is not recommended to cover large surfaces.

Uv Resin or Epoxy: Curing Time

The curing time for UV resin is short because it is made using a torch or UV lamp. UV resin cures in minutes. This is in contrast to epoxy resin which can take several hours or even days. UV resin is a good choice if you have an urgent project.

Uv Resin Vs. Epoxy: Types of Projects

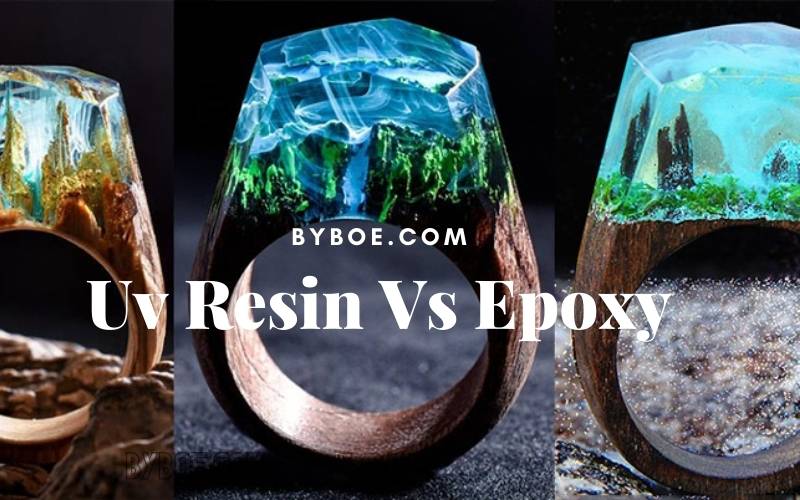

While UV resin can be used in many of the same projects as epoxy resins, not all projects are suitable. It is not recommended for large projects like flooring because UV resin can’t cure without a unique lamp. UV resin is best for flat, small projects such as jewelry.

Also, UV resin has different layers thicknesses than epoxy resin. Epoxy resin can have layers up to 5 cm thick, but UV resin has a maximum thickness of 1mm. The epoxy resin is a good choice if you are looking for resin poured in large deep molds.

Uv Epoxy Vs Uv Resin: Cost

Epoxy resin is the most economical resin. Epoxy resin is less expensive than UV resin, and you don’t need to purchase additional equipment like UV lamps. Epoxy resin can be bought in large quantities, while UV resin is usually sold in smaller volumes.

It would help to compare the initial costs of epoxy resin and UV resin. Also, take into account the long-term durability of both products.

The cost of UV resin is higher than epoxy resin, and it also has a shorter life span. Depending on the location, you may have to repaint your UV resin projects every six to twelve months. Epoxy resin is durable and lasts a long time.

Uv Vs Epoxy Resin: Durability

The product’s durability is another difference between UV resin and epoxy resin. UV resin forms a hard, solid surface in minutes.

However, it is not resistant to heat or scratches. The UV resin can blister or flake if exposed to the sun. Because UV resin must only be applied in thin layers, it is not as strong and durable as epoxy resin.

Epoxy resins generally have a higher quality than UV resin. They are also more durable and have a longer life expectancy.

Epoxy resin needs to be maintained for it to remain strong and attractive. Regular cleaning can prolong the life of epoxy resin and improve its quality.

Epoxy Vs Uv Resin: Shelf Life

It is essential to use resin before its expiration date to ensure the project’s durability. The shelf life for UV resin is only six months. The resin’s physical properties will begin to change after six months.

Epoxy resin is a more durable option than UV resin. It can be stored for up to two years. Epoxy resin can be kept open for six months.

Remember that epoxy resin is more sensitive than other hardeners and should be used within one calendar year.

When to Use UV Resin

UV resin is the right choice if you’re a novice, have limited time, or want to get quick results. You can pour the resin directly from the bottle into a mold or any other surface.

This allows you to save so much time that you would otherwise have spent mixing and measuring. It also makes it easy to boost your confidence and morale by providing instant results.

UV resin is best used with flat and small pieces. It would not be easy to place large amounts of UV resin under a UV lamp.

Keychains, jewelry, cabochons, bezels for earrings and rings, pendants, and keychains are all examples. It can also seal and coat small surfaces to make them waterproof.

When to Use Epoxy

Epoxy is the best choice if you are looking for durable and high-quality products. It is suitable for gift-giving and products for sale.

It is a complex process to prepare and takes a while to cure, but the result is worth it.

Which projects are epoxy suitable for? Epoxy can make 3D objects of any size, large or small. Epoxy doesn’t require UV light activation for a cure. It has a higher maximum layer thickness to cast more oversized items.

Epoxy can be used for almost anything. It can make jewelry, ornaments, dishes, and utility objects such as tumblers, ashtrays, or containers.

It’s also great for larger projects such as sealing floors, countertops, tables, and vanity tops. Epoxy can also be used to bond two surfaces or fill in gaps.

Epoxy Resin Vs Uv Resin: Conclusion

There are many factors to consider when choosing between UV resin and epoxy. The most crucial factor is the intended use of the product. Uv resin is commonly used in automotive plastics to piano keys in various products.

On the other hand, epoxy is used in many areas of industry, such as aviation, construction, and automobile repair. We hope that our article can help you learn more about these products.