Laser engravers are devices that use lasers to create markings or designs on different surfaces. They can be used for various purposes, such as etching or engraving names, logos, or other designs onto different materials. To make a laser engraver, you will need to purchase or build a laser engraving machine, which is expensive. However, several online tutorials can show you How to Make a Laser Engraver?

Table of Contents

- 1 What are DIY Laser Engraving Machines?

- 2 How to Make a Laser Engraver Cutter

- 2.1 These Are the Features of an Engraver

- 2.2 Step 1: Parts list

- 2.3 Step 2: Overview of Laser Engraver/Cutter

- 2.4 Step 3: Assembling

- 2.5 Step 4: Wiring instructions

- 2.6 Step 5: Software installation

- 2.7 Step 6: Software settings

- 2.8 Step 7: Caution, Risks, and Warnings

- 2.9 Step 8: Preparation before Engraving/Cutting

- 2.10 Step 9: Focusing the laser

- 2.11 Step 10: The First Engraving

- 3 How to Make a CNC Laser Engraver? FAQs

- 4 How to Make Your Own Laser Engraver? Conclusion

What are DIY Laser Engraving Machines?

These Laser Engraving Machines are smaller and can be used in your home without taking up too much space. These machines cannot engrave on batch production lines or mass production lines.

They are not designed for engraving smaller objects individually, but instead, they are designed for this purpose. They are smaller in the area and run their software.

If you want to know how does this machine work? let’s check out our guide right now:

Why DIY?

Because they are packed with all the disassembled, these CNC machines are known as DIY laser engraving machines. You will need to follow the instructions or manual with these machines to put together each part.

This activity is great for hobbyists as it allows you to create your DIY laser engraving machine. Despite the difficulties, you must follow these guidelines. It is well worth it.

You can also find many articles on the internet about how to assemble DIY laser engraving machines. These articles will not only show you how to make the diy laser engraver machine but may also include reviews.

The most excellent website is www.instructables.com, where different authors work on DIY engraving machines. You can watch their videos to learn how to build DIY laser machines. It’s project-based work. This is something you might not want.

Before we get into the dazzling models of DIY laser engraving machines, let us show you how to choose the right type of DIY laser engraving machine. Also, what to look out for when buying. We don’t want to make you stop following your passion or hobby.

How to Make a Laser Engraver Cutter

These Are the Features of an Engraver

1. You can engrave wood, plastic, bamboo, and rubber items.

2. Can be used to cut paper, foam, and thin leather

3. Engraving Area: 15cmx20cm

4. Run with Arduino Nano

5. Compatible with Open Source Software

6. Working Power: 5500 MW

I was excited to assemble the kit and was curious to see the results.

This Instructable will share my experiences with the Laser Engraver assembly and the use of the DIY laser cutter/engraver, and the possibilities it offers. It will be beneficial for DIY hobbyists to enhance their work.

Step 1: Parts list

These items are included in the Kits:

1. Aluminium frames / Sticks (2 small, three large)

2. Aluminium Corner Fittings (4 Nos.)

3. Acrylic panels (6 Nos)

4. Stepper Motor ( 3 Nos )

5. Stepper Motor cables ( 3 Nos )

6. Stepper Motor Controller Board ( L1 )

7. Parts Box: 6 small acrylic frames. Screws, timing belts, pulleys, and washers.

8. Safety goggles

9. Laser Module 5.5W

10. USB cable

11. 12V Power Adapter

Step 2: Overview of Laser Engraver/Cutter

Laser cutters can be used in many ways to move from an idea to reality quickly.

“Light Amplification By Stimulated Radiation” is the acronym for LASER.

Working Principle :

Laser Engraver (or cutters) works by focusing high-powered lasers onto a surface. Focused down to the one-thousandth inch, the beam can melt, burn, or even vaporize any material it hits.

There are four major parts to the laser engraving machine:

1. Laser Module: This module emits a high-intensity light beam

2. Stepper Motor: These drive the Laser Module to the desired pints.

3. Controller: Control the laser beam’s direction, intensity, and speed.

4. Surface / On which the laser beam falls/ Materials to be inscribed or cut

The Controller Software loads the design pattern first. The software creates a vector file and then sends it to the Controller Software.

This will guide the beam using the stepper motor. The laser beam’s intensity and engraving speed will affect the quality of the engraving.

Step 3: Assembling

Remove the protective paper layer from the acrylic frames.

Begin by building the bottom rectangular platform. You will need four aluminum rails as well as four corner fittings.

Although I have shown the assembly process in detail in my video, I don’t want to go into the tedious details.

We hope you can understand the situation.

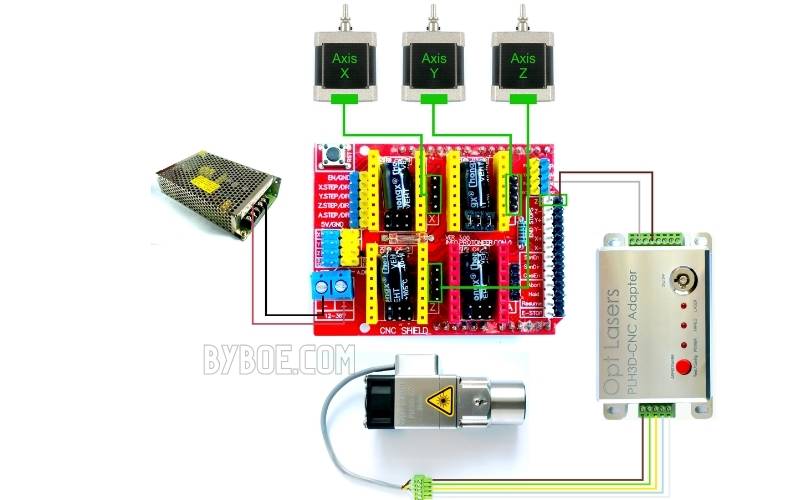

Step 4: Wiring instructions

It is easy to wire. You need to connect the cables to each connector.

Two headers are included in the stepper motor Cable. One is 6 pins long and the other 4 pins. Connect the 6 pin header to your stepper motor.

Follow the instructions to connect the cables to Controller/Driver Board.

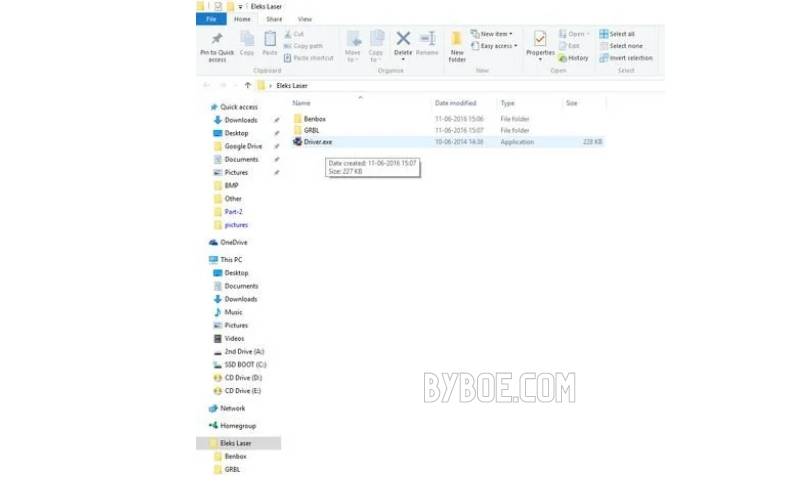

Step 5: Software installation

Plugin the USB cable first.

There are many software solutions on the internet. Inbox, however, will provide the basics for most users. It is easy to use and will take care of the rest.

This guide will show you how to install and use the Bandbox software.

1. Get the Benbox Software.

It can be downloaded from the Benbox website or download the zip file below.

2. Install the driver

3. Confirm that the Driver has been installed successfully

Go to Device Manager->Ports. You will find “USB-SERIAL CH340” (COMXX). Notify the COM port number.

4. Open Benbox to change the language

5. Select the board you wish to use “NANO(328p/LX-Nano”)

6. Update the Firmware: The firmware file can be found in the Bandbox->ROM folder. A green tick will appear after successful updation.

7. Enter the COM port number: The earlier mentioned COM Port number.

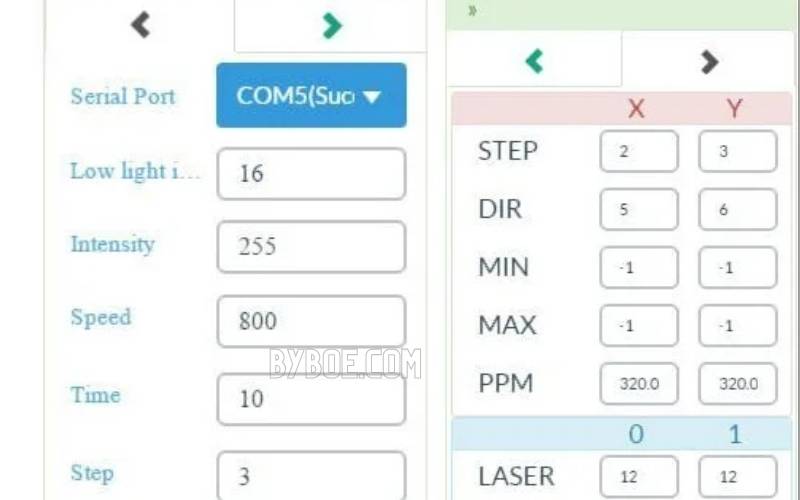

Step 6: Software settings

There are many parameters in the laser engraver software. You can choose different values depending on your actual situation. You can understand each parameter and play with them to achieve the best results.

These are the parameters:

First Page

Intensity: 0-255 controls the voltage (PWM) sent to the laser head. It does not affect most other systems.

Speed: This is the engraving speed at which the laser head moves across a work surface (the main factor in adjusting burning).

Time: This discrete model controls how long the laser stays on for each pixel. A longer time equals more power density.

Step: The distance traveled when you use the x axis control buttons. It does not affect the output.

Carve Mode: Either i one-way (left/right) or ii Z for bi-directional. (left-right/left, etc.). Use the outline to create a shape.

Discrete: This stops the laser at each pixel based upon the time value. It is slower, but it is more precise.

Continuous: The laser pulses continuously and scans the head faster but less precisely.

Second Page

Step – Stepper motor pulse control pins outs from Arduino.

DIR – Stepper motor direction control pins outs from Arduino.

MIN and MAX: To limit control pin (Pulse position modulation)

PPM – Resizing the change drawing scale. PPM should be 320 on both X-axis AND Y-axis for a good result.

LASER: PIN for laser module control. If using PWM mode, the laser on/off should read 12 or 11. There’s a jumper underneath the Arduino Nano that can change this.

SERVO: Control PIN.

Feed Rate: This is the maximum speed the laser can work when it is off.

Notice: You only need to modify the Feed Rate and PPM on the second page. If you’re not an expert, there is no need to alter the other parameters.

Step 7: Caution, Risks, and Warnings

Safety Goggles are mandatory before you move on to the next step. It is mandatory.

This tool is not a toy, but it’s worthwhile. Permanent damage to your eyesight can result from the laser beam.

When engraving or cutting is done, the burning surfaces can produce toxic and harmful fumes. It is essential to understand that burning surfaces can produce toxic fumes and poisonous gases.

When you cut PVC or other vinyl materials, chlorine gas will be released.

Notice: Keep a Fire Extinguisher close to your work area.

Step 8: Preparation before Engraving/Cutting

Laser Engraving Machines do not have a platform or bed for engraving materials.

My first attempt at engraving was placing the laser engravers on top of the table. After a few seconds, I realized that my table was starting to burn.

You can also use other materials depending on your needs.

Place the material to engraving or cutting on the base platform.

Next, adjust the position of the laser head to align it with the material. Press the forward-backward or left-right buttons in the software.

Step 9: Focusing the laser

Focusing the laser beam first is the best way to get a more precise result. My first attempt failed to do so, and the results were terrible.

Turn on the laser switch at the Driver Board for the first time.

Slowly rotate the focusing rings to focus the laser beam on the engraving surface.

Step 10: The First Engraving

Navigate to the menu and click connect.

Drag an image that you wish to engrave/cut. There are many cool designs in the software file. You can choose one.

Next, set the parameters and hit play.

Your engraving is complete!!

These CNC laser engravers can engrave and cut materials such as paper, foam, and thin leather.

How to Make a CNC Laser Engraver? FAQs

Is Laser Engraving Profitable?

Laser engraving businesses can be very profitable if you research and follow the correct procedures. Lasers don’t give away money, just like other industries. To reach your target market, you need to study and build a brand.

Laser engraving has many advantages. It is easy to produce and sell products. The main advantage is the lower cost.

Laser engraving tools are one of the most expensive investments. However, laser engraving tools can be bought for much less than the cost of traditional lasers.

Which Laser Machine Is Best for You?

Excepteur sint occaecat coffee datat no proident, are inculpa qui officia deserunt Mollit anim idesot voluptatimus. Please tell me the answer.

What Are My Options for Professional Engraving?

Let’s look at the laser engraving industry. Here are the top-ranked laser engraving companies in the world.

Can You Make Money Laser Engraving?

Okay. If you are a hobbyist, laser engraving can be a great way to earn extra income. For your Laser engraving business to succeed, you must market yourself and provide excellent customer service.

How to Make Your Own Laser Engraver? Conclusion

A laser engraver is a device that uses lasers to engrave or mark an object. There are many different ways to make a CNC laser engraver, but the most common way is to use a laser diode. A laser diode is a small, laser power used to create images and markings on objects. We hope that our guide was helpful for you.