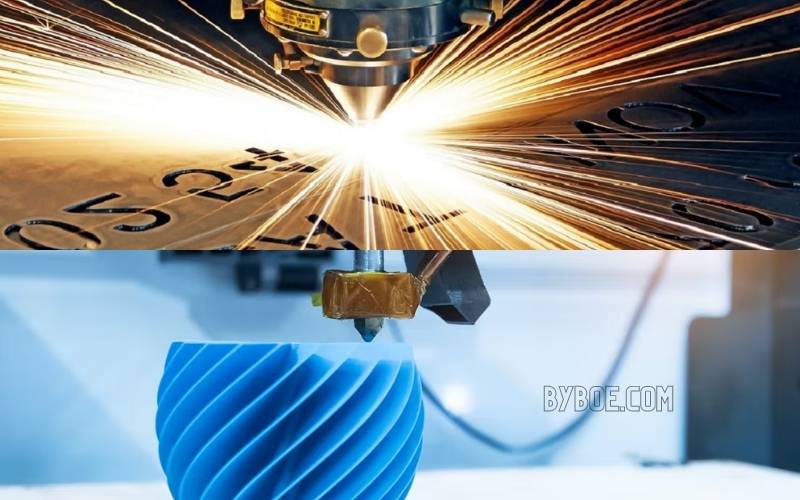

3d Printer Vs Laser Cutter is used for cutting and shaping materials. They are often compared to each other, as people are unsure which is better. In this article, Byboe will reach and contrast the two devices and provide our verdict on the better option.

Table of Contents

What is a Laser Cutter?

Using a laser beam, laser cutters make flat materials into predetermined shapes and patterns. Subtractive manufacturing processes is the process of removing parts to create a product.

You must create the design on a computer before operating the laser cutter. This will allow the selective laser beam to know where to cut. Even if you create intricate designs, this process is usually quite simple.

These machines can do laser engraving or etching. This involves cutting through the material that isn’t too deep but enough to leave a mark on the surface. Laser engravers can work on fragile materials like glass without damaging or shattering the underlying material. Laser engraving and etching can be an independent businesses.

How Does It Work?

Laser engraving machines and laser cutters are two options. Laser engraving engraves your part, while laser cutting uses a powerful laser beam to cut the material. This manufacturing method will transform your 2D design into an actual object.

What Kind of Projects Is It Possible to Create With Laser Cutting?

This manufacturing method can be used to create different materials from acrylic to wood. Is it possible to laser-cut or engrave?

Laser beam cutting is possible with our laser service. You can laser cut acrylic, plywood MDF, cardboard and POM. You will have many options to create your project, including large parts that are cheaper and still retain exciting details. Laser cutting is ideal for creating unique custom items such as decorations or visit cards.

The Benefits of Laser Cutting

Flat surfaces and more significant parts can be worked on

Laser cutting can only be used on flat surfaces. 3D printing cannot. You will need to assemble laser-cut parts if you have 3D objects.

Although it can bring life to your projects and save money, laser cutting is an excellent option for working on large-scale projects. Laser cutting can be used to cut larger surfaces than manufacturing.

This manufacturing method is easy to use to make large parts. We used it at Sculpteo to create tables for an exhibit.

It will allow you to choose the dimensions you want and create your object with great precision.

Some projects are cheaper to make using laser cutting because they may be too large to be 3D printed. Laser cutting is known for its affordability. Laser cutting is a fast and efficient way to make furniture.

Many materials can be used for laser cutting.

Laser cutting is a versatile manufacturing process that allows you to create various custom items such as visit cards, boxes and decorations. MDF (Medium Density Fibreboard) was used to create our tables. Circuit boards could also be made. This video will show you how to laser-cut circuit boards.

It can produce stunning jewelry like 3D printing. But you can also use other materials such as wood. You might find inspiration in our blog post on the best laser-cut wood projects.

Laser cutting is the best option for wood parts. It is impossible to use professional 3D printers for wooden projects, but laser cutting is more adaptable. Laser cutting will produce high-quality objects.

Laser-cutting wood isn’t the only material you have. Acrylic can also be laser cut and offers many options in terms of transparency and colors.

Take advantage of all the design options.

Laser cutting can be used to make many different designs. It is also possible to create complex parts using this technique. Laser engraving can be combined with laser cutting to give your products even more personalization. Laser cutting is the best solution for making precise parts, as you will see.

You should choose the right software for creating your 2D designs if you plan to cut your projects. We have tutorials for laser cutting available on our website if you need any help. This will help you prepare designs for laser cutting.

What Is a 3d Printer?

The additive manufacturing process, where layers are created from the filament by a 3D printer, is called 3D printing. These machines create small three-dimensional objects due to the size of the platform or chamber.

You must first complete the model with 3D modeling software or buy a model compatible with your laser cutting machine from a professional 3D modeler.

The filament is heated to melt it and then sent through a pen-like tip to ensure precision. The 3D printer uses a computer-generated digital model as a template to deposit filament onto a tray or platform.

This creates a solid object that matches the design. You can make filament from various materials, including ABS and PLA. A 3D printer produces a final thing with a rough surface that you can smoothen.

How Does It Work?

3D printing is a method of manufacturing that involves adding material layer-by-layer to a part. This contrasts with subtractive processes, which remove material to create an object.

You will first need to create a 3D model using a 3D modeling program. Next, choose the material you desire. There are many manufacturing methods available. It all depends on what materials you use and the needs of your project.

Powder-based methods allow you to create parts additively using fine polymer powder particles. These particles are then sintered and fused with a laser.

This method can be used to create 3D-printed plastic parts. You can also create 3D printed resin parts using this method. The liquid is heated by ultraviolet light layer by layer, creating rigid parts.

3D printing is possible:

- Plastics are made with technology such as Selective Laser Sintering and Multi Jet Fusion.

- Resins made with technology such as Polyjet or CLIP technology

- Metals using technologies like Selective Laser Melting or Direct Metal Laser Sintering.

These technologies all allow you to print with different 3D printing materials. There are many options, so 3D printing can prove to be an extremely convenient manufacturing method for many projects. You will need to ensure that the 3D printing materials are appropriate to your parts.

What Kind of Projects Is It Possible to Create With 3d Printing?

3D printing allows you to use a variety of 3D printing materials. This makes it possible to create unique projects like 3D printed homes, jaws, prostheses, and fashion accessories.

This technology is essential in many industries, including fashion, architecture, healthcare and fashion. You can even create electronics projects like 3D printed robots.

Benefits of 3d Printing

Additive manufacturing allows for production and prototyping.

You can produce high-quality prototypes with additive manufacturing. A 3D modeling program will allow you to create complex or simple designs and make as many iterations at a lower cost.

You can create prototypes and finished products of high quality using additive manufacturing at a much lower cost than other techniques like injection molding. 3D printing will help you save time and money and improve the product development process.

Create complex designs

Your company could be an asset with 3D printing. Everything is now 3D printed, from clothing accessories to mechanical devices. Printing any item, even complex designs, with a professional 3D printer is now possible.

Take advantage of the many 3D printing materials.

This is a great way to make complex, resistant parts in one piece. You can choose from many materials, and each one will meet your needs.

Is your part heat-resistant? Flexible? Are you looking for special finishings? Our material pages will help you find suitable materials and all options for your project.

3D printing is the best option for medical professionals who require biocompatible materials. Our biocompatible resins can be used to make prostheses and other medical devices. This would not be possible using laser cutting. Additive manufacturing is the best solution for this type of project!

3D printing is the best method to make a 3D metal object. You can even 3D print aluminum or stainless steel.

3d Printer Vs Laser Cutter: Side by Side Comparison

Materials Used in Laser Cutter Vs 3d Printer

To build 3D objects, most 3D printers use plastic filament. Some biodegradable filaments and filaments can be mixed with other materials to work in specific machines.

You can also make multi-colored designs with filaments. The main problem with filament is its weakness. Some filament can break, bend or degrade over time.

Some 3D printers can print objects made from metal and biocompatible plastics. However, you cannot switch between materials. You may need two different 3D printers to print metal and filament designs.

A laser cutter is an excellent choice if you are looking for something that can be used with many materials. Fiber Laser cutters can be used on wood, fabric, acrylic, and composite materials.

Laser cutters are also capable of etching glass and metal. It is possible to quickly switch between materials without replacing any parts on your laser machine.

3d Printer and Laser Cutter: Speed and Accuracy

Software is required to plan your final design, regardless of using a 3D printer and laser cutter. Some machines come with software and hardware that allows you to program your method right into the machine. Others require you to create your initial design on another computer system before transferring it to the device.

Laser cutters can produce a finished product faster than 3D printers. Laser beams can be used to cut into materials with high precision.

This allows you to have complete control over the final product. Laser cutters can cut down to 0.006 inches in depth, which allows for intricate designs that would be impossible with other methods.

Laser printers are fast enough to allow you to test multiple designs at once to find the one that works best for you. Laser-cut items can be made in a shorter time, making it easier to stock up during busy times.

3D printers might have difficulty translating a 3D model’s design into a finished object. This is because any flaws that are not visible on the computer screen could cause bulges or holes in the final product.

A long stem with a bulb at its top might look great on the computer screen, but the branch will not be strong enough to support the bulb once it is printed.

Sometimes, 3D printers jam. This means that you will need to remove any built-up material before moving on with the 3D printing job.

Laser cutters and 3D printers can be safely used in a workshop environment or maker space with sufficient ventilation. Although a laser cutter can produce smoke and fumes, these will dissipate quickly in a well-ventilated area. The machines don’t make much noise, so ear protection is not necessary when using a 3D printer or laser cutter.

Making 3D Objects with a Laser Cutter Vs 3D Printer

After creating the flat pieces, 3D objects can be assembled using a laser cutter. This works well for angular items such as pyramid-shaped or boxes.

You can personalize your creations with the laser cutter’s ability to engrave materials. A panel or plate can be created with a name or phrase to attach to your final product.

The 3D printer creates the object from scratch using filaments layered on top. This allows for smooth surfaces and curves instead of sharp edges.

Your 3D printer’s size limits what you can make. You can only create objects as big as your tray or chamber. You can print multiple jobs to create a larger entity and then combine the individual pieces to make it larger.

Cost Differences Between Laser Cutters and 3D Printers

There are many price options for laser cutters and 3D printing, but 3D printers are generally less expensive than laser cutters. 3D printers tend to have higher operating costs, but filament can be costly, and parts like the extruder nozzle may need replacement. There are different spools for each color.

You may also need to clean the extruder between filament types. These machines are used for prototyping and not large-scale manufacturing because of the high cost of making individual 3D printed objects.

3d Printer Versus Laser Cutter: Conclusion

3D printers can create three-dimensional objects by laying down successive layers of material, while laser cutters use lasers to cut away fabric from a sheet of stock. Both have their advantages and disadvantages, but the overall winner depends on the user’s specific needs. We hope that our comparison was helpful for you.